From sturdy cast iron to versatile PVC, every type of pipe plays a crucial role in our homes and cities. But what happens when they wear down?

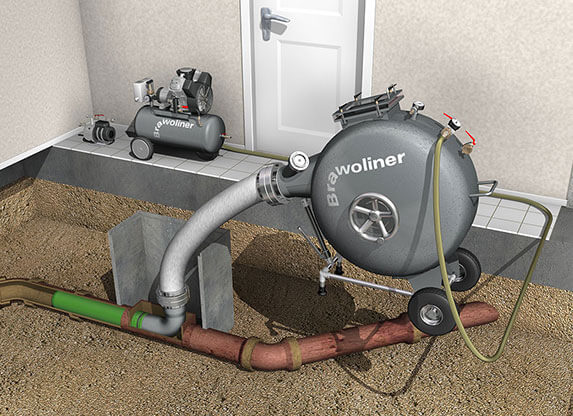

Enter pipe relining, an innovative leap in modern plumbing. This technique isn’t just a fix; it’s a tailored solution that brings efficiency and longevity to most types of pipe.

In this article, we’ll explore how pipe relining adapts to meet the unique demands of different pipe materials.

Adaptable Solutions for PVC Pipes

PVC pipes, widely used in modern Australian plumbing, demand specific repair solutions to maintain their integrity and functionality. Pipe relining is an ideal option for these commonly used pipes, offering a seamless and effective repair method.

Here’s how this advanced technique is particularly well-suited to PVC pipes:

PVC Compatability

The pipe relining process is expertly tailored for PVC pipes. It ensures a perfect fit, adapting to the pipe’s size and shape. This provides an effective seal against leaks and cracks.

Lifespan Extension

Relining PVC pipes isn’t just about repair; it’s about reinforcement. This process significantly extends the life of PVC pipes by adding a durable inner layer that protects against wear and tear.

Enhanced Durability

With pipe relining, PVC pipes gain an extra layer of strength. The relining material is robust and resistant to common pipe issues, such as corrosion and damage from tree roots.

Cost-Effective Maintenance

By opting for relining, homeowners can avoid the higher costs associated with replacing PVC pipes. The process is less invasive and more cost-effective. It offers a practical alternative to traditional pipe replacement methods.

Quick and Efficient

Pipe relining for PVC pipes is a swift solution compared to traditional repair methods. This efficiency means less disruption to your property and a quicker return to normalcy for you.

Strengthening Metal Pipes Through Relining

Metal pipes are most commonly found in older properties. They’re more susceptible to corrosion and rust, which means they greatly benefit from advancements in pipe relining technology.

This method enhances the durability and functionality of metal plumbing systems. Here’s some more information:

Corrosion Resistance

One of the main advantages of relining metal pipes is their ability to resist corrosion. The relining process involves inserting a liner that acts as a protective barrier, shielding the metal from moisture and other corrosive elements. This barrier significantly reduces the risk of rust and prolongs the life of the pipes.

Enhanced Structural Integrity

Pipe relining reinforces the structural strength of metal pipes. The liner material bonds with the existing pipe, essentially creating a pipe within a pipe. This added layer not only fixes current leaks or weak spots but also prevents future issues, creating a more robust plumbing system.

Leak Prevention

As metal pipes age, they become prone to leaks. The relining process effectively seals any existing leaks and prevents new ones from developing. This preventative measure is crucial for maintaining the overall health of your plumbing system.

Long-Term Solution

Relining metal pipes isn’t just a quick fix; it’s a long-term solution. The durability of the relining materials means that once the pipe is relined, it can last for years and years without needing further repairs. It’s a wise investment for property owners.

Cost-Effectiveness

Compared to replacing metal pipes, relining is a more cost-effective option. It requires less labour and time, and there’s no need for extensive excavation, which can be costly and disruptive.

Resilient Solutions for Clay Pipes

Clay pipes are often used in older plumbing systems, like metal pipes. They present unique challenges, such as their susceptibility to cracks and tree root intrusions.

Pipe relining offers an innovative and efficient solution to these issues. Here’s why:

Crack and Root Intrusion Prevention

One of the key benefits of pipe relining for clay pipes is its effectiveness in preventing cracks and root intrusions. The relining process involves inserting a durable liner that adheres to the interior walls of the existing pipes.

The liner acts as a shield, blocking roots from penetrating and sealing any existing cracks. This not only resolves current problems but also prevents future damage.

Seamless Repairs

Pipe relining provides a seamless repair solution for clay pipes. Unlike traditional methods that require digging up and replacing damaged sections, relining creates a new, smooth, and strong pipe within the old one. This trenchless method is less invasive, meaning you can preserve your landscaping and any structures around the pipe.

Extended Lifespan

Relining clay pipes significantly extends their lifespan. The new inner lining is designed to withstand various environmental factors, leading to a longer service life compared to untreated clay pipes.

Cost-Effective Restoration

Repairing clay pipes with the relining method is more cost-effective than full replacement. It reduces labour and material costs and minimises disruption to your property.

Improved Flow and Functionality

The smooth surface of the relined pipe enhances water flow and functionality. This improvement helps in reducing the likelihood of future blockages and maintaining efficient drainage.

Tailored Solutions for Cast Iron Pipes

Cast iron pipes are common in older homes and historic properties. They require a careful approach to maintenance and repair.

Pipe relining offers a tailored solution that effectively addresses the unique challenges of cast iron plumbing:

Erosion Resistance

One of the primary benefits of pipe relining for cast iron pipes is its ability to resist erosion. The process involves installing a protective liner inside the existing pipes.

Durable Liner

The liner, often made of epoxy resin, forms a barrier against further deterioration caused by age and use. It effectively seals off any corroded areas, significantly reducing the risk of future erosion and extending the pipe’s lifespan.

Preserving Historical Properties

For historic homes with cast iron plumbing, the non-invasive nature of pipe relining is a significant advantage. Unlike traditional methods that might involve digging up and replacing old pipes — potentially damaging the property’s historical integrity — relining works within the existing pipe structure.

Efficient Installation Process

The installation of liners in cast iron pipes is efficient and minimises disruption. This process, which typically involves inserting any epoxy resin-coated liner, can be done relatively quickly compared to traditional pipe replacement jobs.

Enhanced Functionality

Apart from preventing erosion, pipe relining improves the overall functionality of cast iron sewer and drainage systems. The smooth surface of the relined pipes facilitates better water flow and reduces the likelihood of blockages.

Fibreglass and Composite Pipe Solutions

Fibreglass and composite pipes, while known for their durability and versatility, can face specific challenges over time.

Pipe relining is a practical and efficient solution for these types of pipes. Here’s why:

Enhanced Performance

Relining fibreglass and composite pipes can significantly enhance their performance. This process involves the insertion of a new liner inside the existing pipe, which addresses any potential weaknesses like minor cracks or joint failures.

Fortified Pipes

The relined pipe fortified from within, can handle higher pressures and resist common problems such as corrosion and wear. This reinforcement ensures that the underground pipes continue to function effectively for a more extended period.

Cost-Effective Repair

Compared to the total replacement of fibreglass or composite pipes, relining stands out as a more cost-effective solution. Relining eliminates the need for extensive excavation, reducing the direct costs associated with the job and minimising disruption to your property.

Minimal Disruption

Pipe relining for fibreglass and composite pipes involves a less intrusive method. Plumbers can often complete the job without major excavation, which means less mess and a quicker return to normal for homeowners and businesses. This aspect is particularly crucial in densely populated areas or locations with limited access.

Long-Term Problem Solver

Pipe relining offers a long-term solution for common problems in fibreglass and composite pipes. By addressing the root cause of issues like leaks or flow restrictions, relining extends the life of the existing pipes, ensuring they remain functional and reliable for years to come.

Pipe Relining: A Universal Solution for Diverse Plumbing Needs

Pipe relining proves to be an exceptionally versatile solution, adept at addressing an array of pipe materials — from PVC and cast iron to clay and composite. This technique stands out for its ability to adapt to a whole host of different challenges. It brings long-term integrity and functionality across various types of pipes.

Whether dealing with the unique demands of historic cast iron pipes or the specific challenges of modern PVC systems, pipe relining offers a reliable, cost-effective solution.

For property owners looking for a versatile and long-lasting solution to their plumbing needs, pipe relining presents an ideal choice. It’s a smart investment that caters to a diverse range of plumbing situations.

If you’re considering pipe relining for your property, reach out to our team at The Relining Company today. With our expertise and quality service, we’ll provide the best pipe relining and plumbing solutions tailored to your specific needs.

Get in touch today to explore your options and secure the benefits of this innovative method. To learn more, check out our FAQ.

Back to Top